Project Info

Category

Date

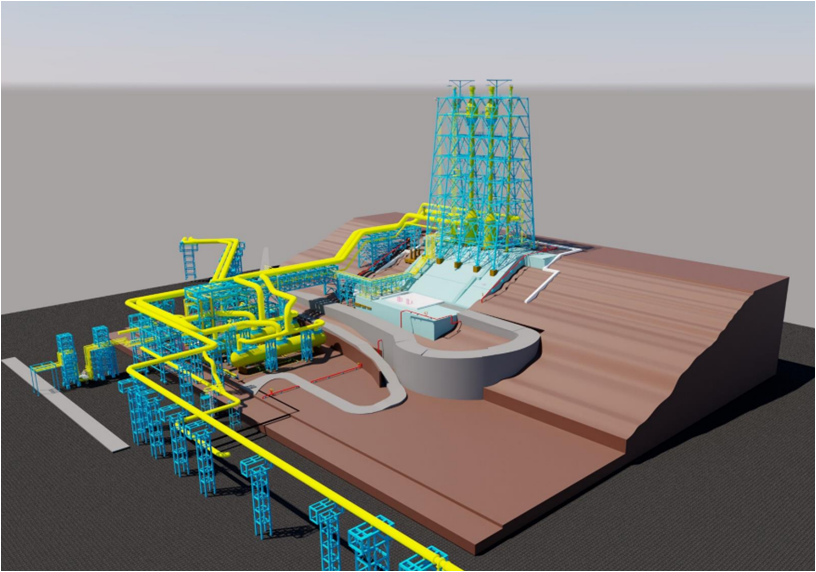

NRL Refinery Flare

Detail Piping Engineering including 3D modelling & Pipe stress analysis of the Refinery Hydrocarbon Flare system comprising Flare KO Drums, KOD Pumps, Water Seal drum, Flare Riser, Molecular Seal, Flare Tip, Flare Headers from B/L to KOD and From KOD to Water seal Drum, max header size 38 ”. Flame Front Generator with shelter. Derik Structure common for all flares with stairs/ ladders, operating platforms for mounting and demounting operations. All piping within B/L with steam tracing wherever applicable.

Project Details

1

Owner

Numaligarh Refinery Ltd.

2

PMC

Engineers India Ltd.

3

Role

Detail Engineering – Piping & Stress Analysis

4

Software used

PDMS, Flexibility Analysis Software

5

Project

Flare Package

6

Location

Numaligarh

7

Client

Airoil Flaregas Pvt. Ltd.

8

Status

Completed