Project Info

Detail Piping Engineering including 3D modelling & Pipe stress analysis of the Refinery Hydrocarbon

Category

Date

August 26, 2021

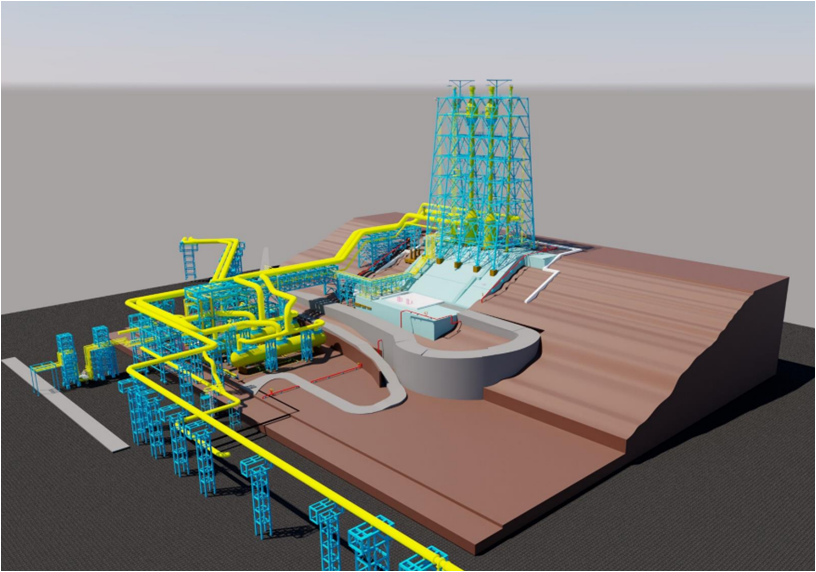

HRRL Refinery Flare

Detail Piping Engineering including 3D modelling & Pipe stress analysis of the Refinery Hydrocarbon Flare system (LP and HP), DFCU LP Flare System, Polymer LP Flare System, C4 Acetylene Flare System, Sour Acid Flare System, Comprising Flare KO Drums, KOD Pumps, Water Seal drum, Flare Riser, Molecular Seal, Flare Tip, Flare Headers from B/L to KOD and From KOD to Water seal Drum, max header size 100”. Flame Front Generator with shelter. Derik Structure common for all flares with stairs/ ladders, operating platforms for mounting and demounting operations. All piping within B/L with steam tracing wherever applicable.

Project Details

1

Owner

HPCL Rajasthan Refinery Ltd.

2

PMC

Engineers India Ltd.

3

Role

Detail Engineering – Piping & Stress Analysis

4

Software used

PDMS, Flexibility Analysis Software

5

Project

Rajasthan Refinery Project

6

Location

Pachpadra, Barmer (India)

7

Client

Airoil Flaregas Pvt. Ltd.

8

Status

Completed